Practical Examples

By the following examples, we would like to explain the carried out work.-

Repair rotor blade

Repairing a laminate fold on Rodend on a LM 25.5 rotor blade. Damage was grinded. The new laminate layers were rebuilt by vacuum. Subsequently, the repair was annealed with a heating mat. The surface finish was produced with gel top coat. You need an offer?

-

Repair Tip-carbon shaft

A by debris damaged carbon shaft of a LM 29.0 tips. This was dismantled by MB Bladeservice and repaired: damaged laminate removed and sanded, rebuilt missing laminate in three steps under vacuum, sanded, re-contour by using a stencil and ground flat and annealed according to the manufacturer. You need an offer?

-

Repair Tip-Mechanics

Tipmechanik damage and cracks at rope be checked and repaired by an expert of our trained staff. You need an offer?

-

Repair tip-rib (Fish, Fisk)

Broken tip-rib (fish, Fisk) cut out. Adapted new tip-rib and bonded. Outbreaks repaired. You need an offer?

-

Repair tip brakes

By using rope technique we are able to assemble or disassemble the tip brakes. So we are able to repair the damages on the floor. You need an offer?

-

Repair erosion protection

Bad weather creates strong erosions on the leaves. This reduce the profit of wind turbines by up to 15%. We repair any kind of erosion damage and restore the blade profile at the leading edge. To protect the blade we can use a Leading Edge or BladeProtect (liquid film). You need an offer?

-

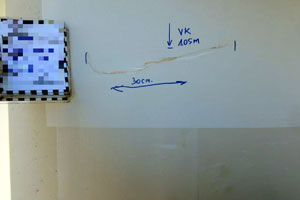

Repair lightning damage

Damage caused by lightning are expertly repaired by us. The damaged laminate was sanded, scarfed and laminated again (laminate according to plan) and then sealed with a Gel-/Topcoatschicht. You need an offer?

-

Test protocol lightning protection system

At WTG rotor blade (outside) according to EN 62305-3 Supplement 3. Type of inspection: inspection according to the "working guidelines for testing the condition of the flash system of wind turbines" the expert advisory board of the BWE. Compliance with the EN 61400-24:2012 Din (VDE 0127 Part 24) "Wind turbines-Part 24: Lightning protection". Testing gauges: METRAOHM 413 with 50m measuring performance, measuring range 0 to 199 Ω according to DIN VDE 0100 part 610 and EN 61557-4 (VDE 0413, part 4). Test measures: Visual inspection of lightning protection, function, wear and lightning strikes. Checking the conductivity of the test compounds with 200 mA (Low-). Line resistance of the cable is calculated out. You need an offer?

-

Tower Cleaning

By using a special system for climbing the tower it is possible for us to clean the tower quickly and cheap - for example after an oil damage. You need an offer?

Back to our services ...

Service

Do you have questions about any of our application examples? We would be glad to help you! MB Bladeservice GmbH- Address:Otto-Hahn-Strasse 3-5

- D-37574 Einbeck

- Phone:+49 (0) 5561 8280916

- Fax:+49 (0) 5561 8280917

- E-mail:info@mb-bladeservice.com